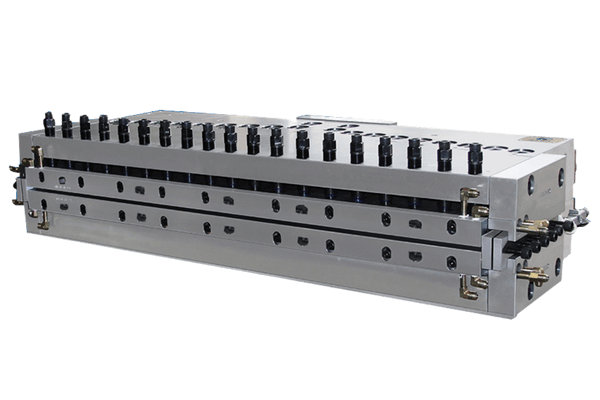

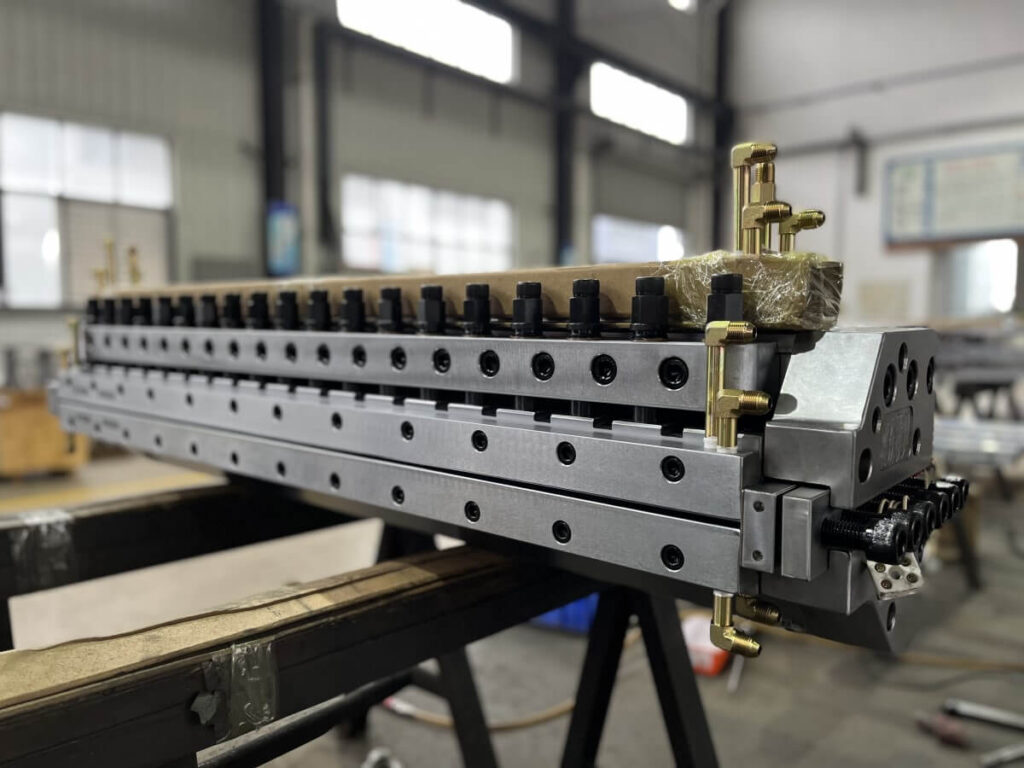

More than 10 years professional experience in extrusion T-die designing and manufacturing, with actual data to develop extrusion dies with perfect flow channel design. Our t-die can help improve product quality and reduce the process of material consumption costs. It is a long-term savings for customers.

Our company’s engineers have the ability and experience to independently design and develop sheet molds of various densities, widths, and thicknesses, and have rich ability and experience in adjusting processes and formulas. A professional technical team has been formed for Customer service, we not only provide mold products, but also have the ability to provide a full range of technical support!

Sharpened tools help to do good work, we have advanced manufacturing technology and equipments, advanced equipments and technology provide reliable guaranty to be geared to international standards.

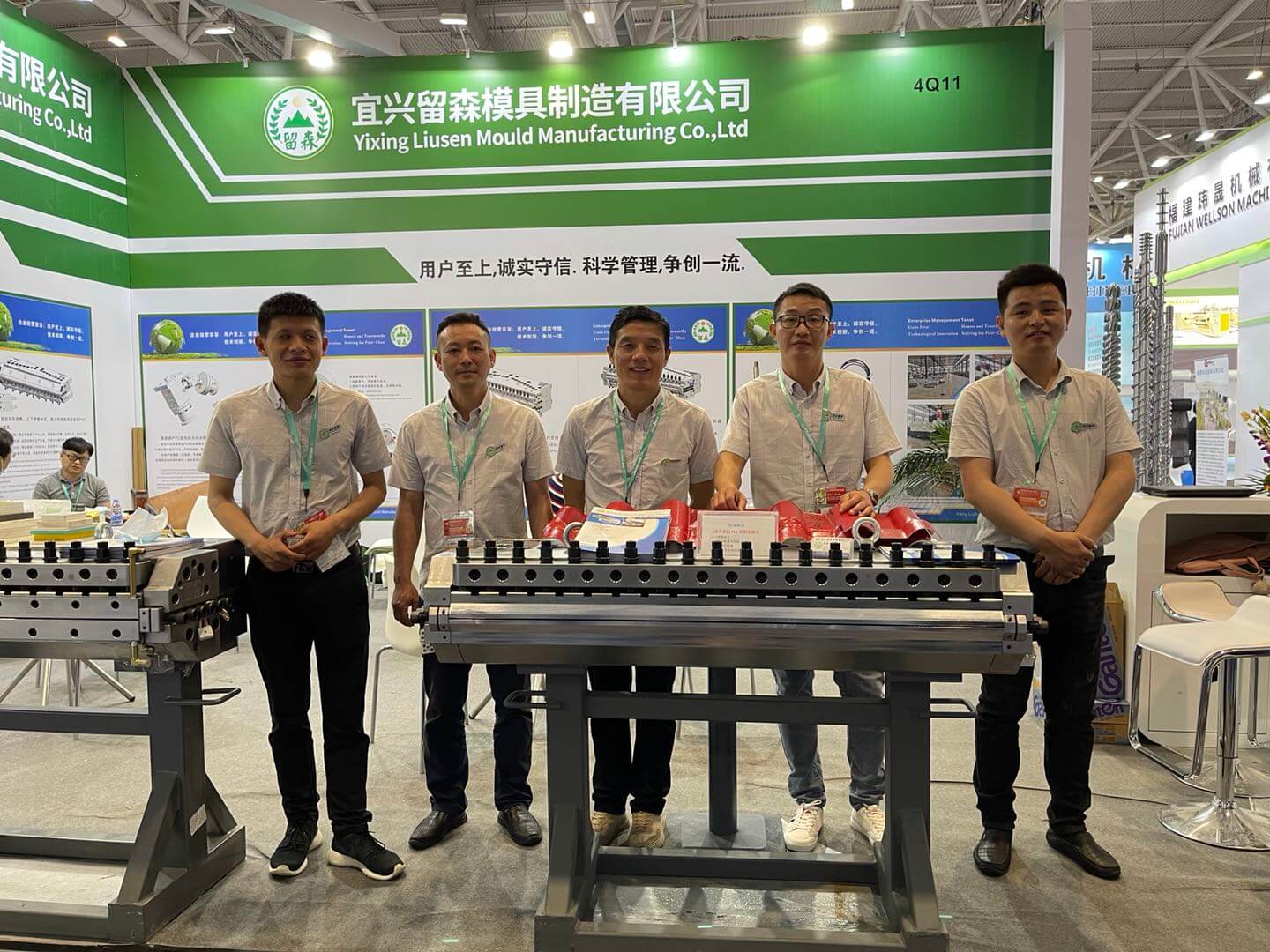

LIUSENMOULD has obtained a number of national certificates for PVC extrusion molds

The Company has advanced CNC machine center, Taiwan large precision surface grinder, radial drill and other complete mould manufacturing equipments. LIUSENMOULD is a manufacturing-type enterprise which is professional in development and design of plate moulds, products machining and manufacturing, as well as after sale service and track services.

LIUSENMOULD has excellent technical talented team and advanced technical equipments, every product implies our team power and creative spirit, with rigorous work attitude and excelsior development concept t, to design the perfect products for customers.

Continuous improvement and innovation, providing customers with better molds, allowing customers to earn more profits. Customers will trust "LIUSENMOULD", the company can survive and develop, and realize the "win-win model".

The needs of customers and the market are our development direction. Continuous research on the needs of customers and the market, and the development of new products to meet the needs of customers can enable the company to continue to develop.

LiusenMould has always insisted on technological innovation, and customer feedback is the basis for our quality improvement.

Q1: What material of extrusion product, PVC, PP, PS, ABS, PC or PET?

Q2: Could you please provide me diamensional drawing, structure drawing and photos of your product?

Q3: How many meters per gram is the weight of your required product? (?m/g)

Q4: What is the extrusion speed? (?m/min)

Q5: What is the model of your extrusion machine?

We can produce if you can answer the following question.

Just leave your question & you are done. You will get back in shortest possible time. We will provide you with free plans and quotations.

Yixing City Formwork Science and Technology Industrial Park.

No. 58, Moyu South Road, Anting Town, Jiading District.

Powered by LinsenMould. All rights reserved.

We will contact you within 1 working day, please pay attention to the email with the suffix “@liusenmould”.